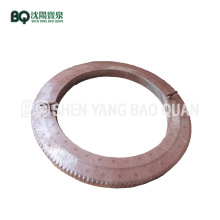

Wind Turbine Bearing in China

Product Description

Closures: Open, Metal Sealed, Rubber Sealed, Nylon Sealed Vibration Level Codes: V1, V2, V3 Precision Rating: Z1, Z2, Z3 Delivery Date: Within 20-30days Normally / as Requested Trademark: LDB Origin: Luoyang, China Accuracy Lever: Abec-1, Abec-3, Abec-5 Clearance: C2, C0, C3, C4, C5 Supply Ability: 2 Sets Per Month Export Markets: Global Specification: ISO Wind Generator bearing, wind turbine bearing

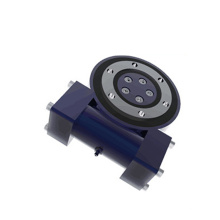

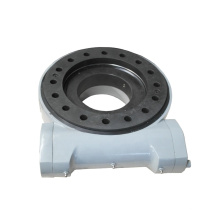

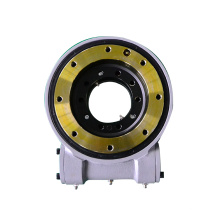

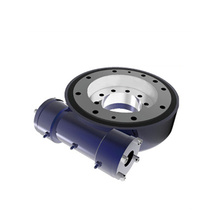

Structure of Yaw and Pitch Bearing

Generally, yaw and pitch bearing stuctures are single row ball slewing rings four-point contact bearing and double row ball slewing ring four-point contact bearing. And both these two types of bearings can be further divided into bearings without gears, bearings with internal gears, bearings with outer gears according to gear position.

Material and heat treatment

Rolling elements in yaw and pitch bearing are made of GCr15 or GCr15SiMn bearing steel according to GB/T 18254-2002. Their heat treatment should comply with JB/T 1255-2001. Other materials with similar or better properties can also be used.

The material of rings in yaw and pitch bearing is 42CrMo or others that meets technique requirements according to GB/T3077-1999. Hardness after hardening and quenching should be 229HB~269HB, for raceway after quenching 55HRC~62HRC. The effect hardened thickness of race way should meet the requirement.

Tolerance and clearance

Generaly radial and axial clearance of yaw bearing is0~50μ M. They can be adjusted according to customer requirement. Radial and axial clearance of pitch bearing is less than 0.

Starting torque

Please consult with Technique Department of our company

Lubrication hole

Yaw and pitch bearings is lubricated through lubrication hole, which is screwed hole with M10X1

Seal

Fow yaw and pitch bearing, seal material should be NBR according to HG/T 2811-1996 or better material. We use world famous seal with good performance and reliable quality for our pitch and yaw bearing.

Spacer and cage

Yaw bearing of our company has spacers that are self-lubricated and can compensate for lubrication when lubrication oil is unevenly distributed in order to maintain best lubrication status between balls and groove contact areas.

Our pitch bearing uses integrated steel cage which has simple structure and can save space and accommodate more balls to increase load capacity. Compared with traditional segmented cage, integrated cage is easier to assemble and more stable and reliable.

Preservative treatment

For yaw and pitch bearing, except for groove and gear all other surfaces should be applied thermal spraying anti-corrosion treatment according to GB/T9793-1997 and GB/T8427-1996. When applied zinc coating, the thickness of anti-corrosion should be no less than 160μ M. Other anti-corrosive treatment shall be applied if it meets performance requirements of machines.

Contact us if you need more details on Wind Turbine Bearing in China. We are ready to answer your questions on packaging, logistics, certification or any other aspects about China Wind Turbine Bearing、China Slewing Bearing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Structure of Yaw and Pitch Bearing

Generally, yaw and pitch bearing stuctures are single row ball slewing rings four-point contact bearing and double row ball slewing ring four-point contact bearing. And both these two types of bearings can be further divided into bearings without gears, bearings with internal gears, bearings with outer gears according to gear position.

Material and heat treatment

Rolling elements in yaw and pitch bearing are made of GCr15 or GCr15SiMn bearing steel according to GB/T 18254-2002. Their heat treatment should comply with JB/T 1255-2001. Other materials with similar or better properties can also be used.

The material of rings in yaw and pitch bearing is 42CrMo or others that meets technique requirements according to GB/T3077-1999. Hardness after hardening and quenching should be 229HB~269HB, for raceway after quenching 55HRC~62HRC. The effect hardened thickness of race way should meet the requirement.

Tolerance and clearance

Generaly radial and axial clearance of yaw bearing is0~50μ M. They can be adjusted according to customer requirement. Radial and axial clearance of pitch bearing is less than 0.

Starting torque

Please consult with Technique Department of our company

Lubrication hole

Yaw and pitch bearings is lubricated through lubrication hole, which is screwed hole with M10X1

Seal

Fow yaw and pitch bearing, seal material should be NBR according to HG/T 2811-1996 or better material. We use world famous seal with good performance and reliable quality for our pitch and yaw bearing.

Spacer and cage

Yaw bearing of our company has spacers that are self-lubricated and can compensate for lubrication when lubrication oil is unevenly distributed in order to maintain best lubrication status between balls and groove contact areas.

Our pitch bearing uses integrated steel cage which has simple structure and can save space and accommodate more balls to increase load capacity. Compared with traditional segmented cage, integrated cage is easier to assemble and more stable and reliable.

Preservative treatment

For yaw and pitch bearing, except for groove and gear all other surfaces should be applied thermal spraying anti-corrosion treatment according to GB/T9793-1997 and GB/T8427-1996. When applied zinc coating, the thickness of anti-corrosion should be no less than 160μ M. Other anti-corrosive treatment shall be applied if it meets performance requirements of machines.

Contact us if you need more details on Wind Turbine Bearing in China. We are ready to answer your questions on packaging, logistics, certification or any other aspects about China Wind Turbine Bearing、China Slewing Bearing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Slewing Bearing

Premium Related Products

Other Products

Hot Products

Slewing Ring for Tower CraneSupply High Quality Slewing Ring for Stacker and ReclaimerSlewing Ring for Ship Loaders and Ship Unloaders MachinesHot Sale High Speed and Low Noise Spherical Roller BearingSplit Bearing Cylindrical Roller BearingFour-Row Taper Roller Bearing for Cold Rolling Mill Stf215kvs2851egWandan slewing bearing with external gearMain Gear For Spur GearSingle Row Crossed Roller Slewing BearingDouble Row Slewing Ring Inner GearTorriani Gianni slew Bearing Replacement I. 1100.32.00. CKato Excavator Swing Ring (HD700-5)slewing Bearing for phosphating treatment for 8t truck craneHeavy duty three Row Roller Slewing Bearing 131.32.1800Solar tracker slewing drive manufacturerslewing ring bearing for 6t truck crane